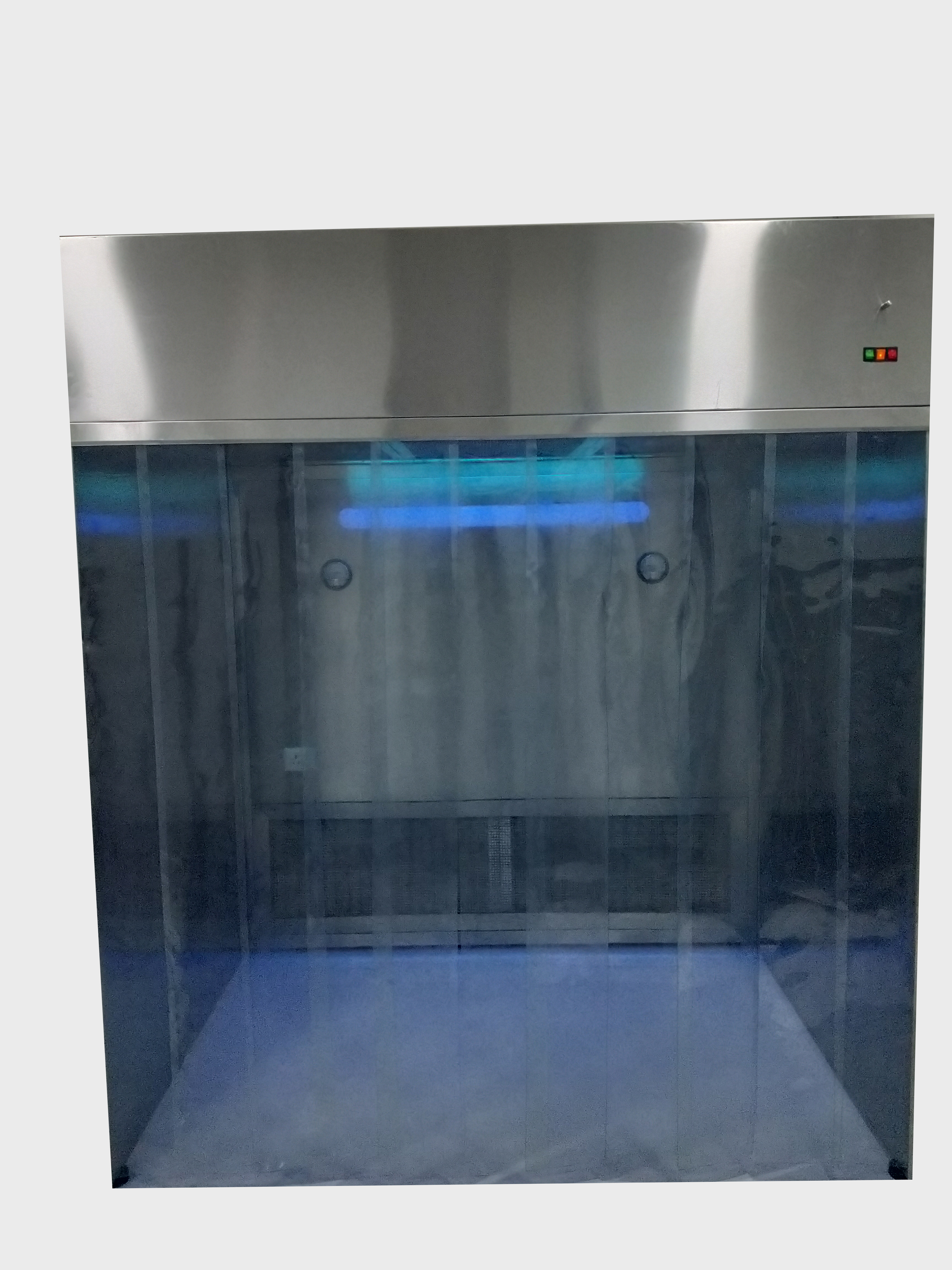

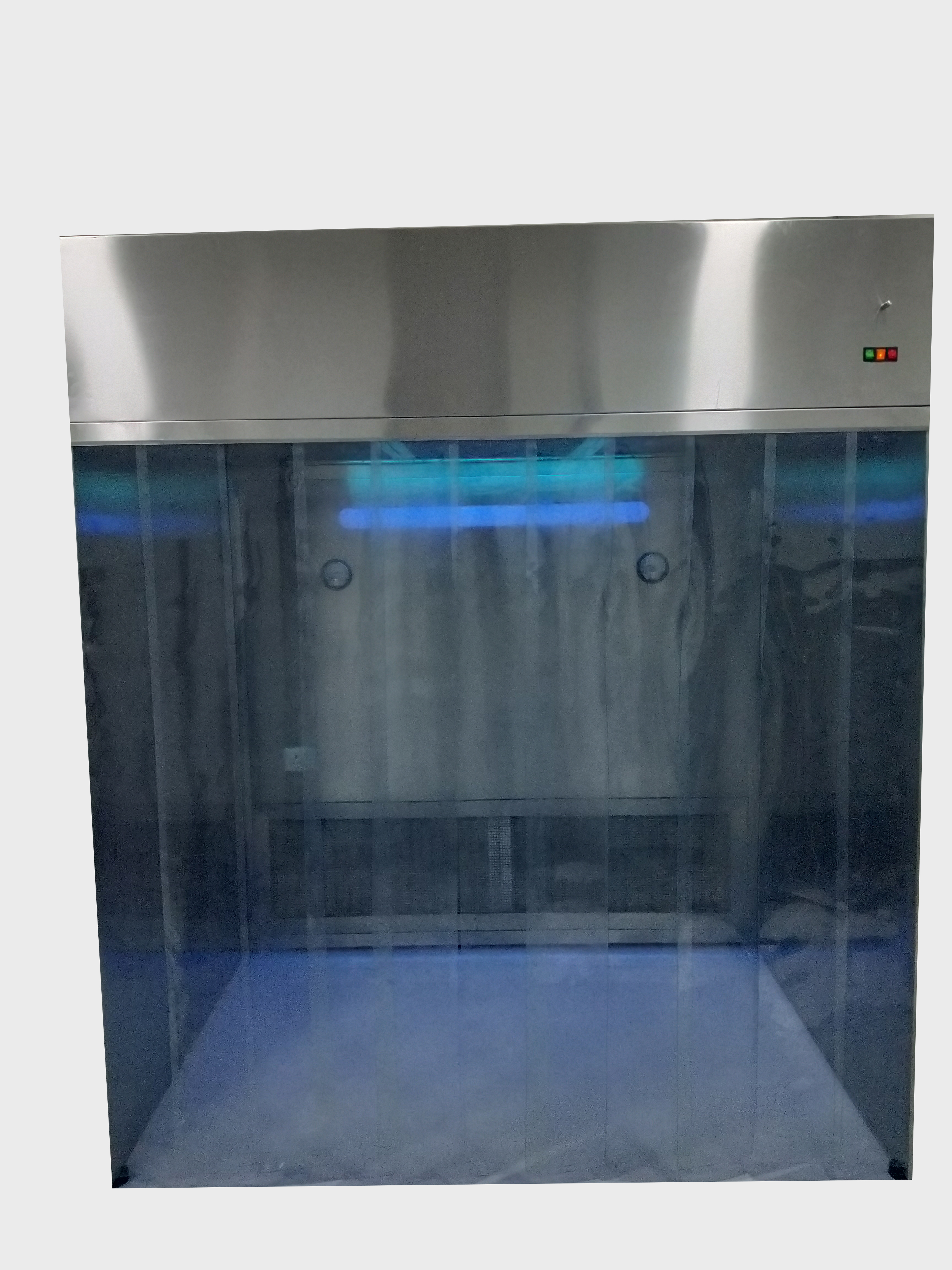

Reverse Laminar Air Flow

Price 100000 INR/ Unit

Reverse Laminar Air Flow Specification

- Filters

- HEPA Filter- Minipleated HEPA Filters down to 0.3mic. particulate at an efficiency of 99.999% (EU14) duly tested on DOP tested with SS-304 Protective Grill

- Frame Material

- Stainless Steel

- Filter Type

- HEPA Filter

- Voltage

- 230 Volt (v)

- Application

- Pharmaceutical Industries, Laboratories,

- Dimension (L*W*H)

- As per Requirement Millimeter (mm)

- Type

- Other

- Power Consumption

- 230 V, 50Hz, Single Phase Volt (V)

- Material

- Stainless steel

Reverse Laminar Air Flow Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cheque

- Supply Ability

- 25 Units Per Month

- Delivery Time

- 4 Week

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Packaging Details

- Standard Quality

- Main Domestic Market

- All India

- Certifications

- ISO 9001 - 2015 NSIC

About Reverse Laminar Air Flow

Reverse Laminar Air FlowSampling / Dispensing Booth (RLAF) unit eliminated powder contamination to protect the operator and the Surrounding environment. it is designed to handle powder under aseptic conditions for optional G.M.P. Technical Specification: Cleanliness Class 100 / ISO CLASS 5 / M 3.5 AREA Velocity at Grill 90 + 10 FPM Material of Construction S.S 304 HEPA Filter Mini pleated HEPA Filters down to 0.3mic. particulate at an efficiency of 99.999% (EU14) duly tested on DOP tested with SS-304 Protective Grill Intermediate Filter Micro Filter down to 5mic. Particulate at an efficiency of 99% (EU9) enclosed in aluminum frame with epoxy sealing (Washable Type) Pre-Filters Pre Filter down to 10mic. Particulate at an efficiency of 95% (EU4) enclosed in aluminum frame with epoxy sealing (Washable Type) Blower Assembly Dynamically and statically balanced motor and blower Side Panels Both side SS-304 Double Skinned PUF Insulated Panel Front Door Do with Flexible PVC Strip Curtain Electrical 1) On/Off Switch2) Fluorescent Light3) U V Light4) Auxiliary Socket Pressure Gauge Magnahelic Gauge one is to check the pressure drop across the HEPA filter and other for pre and micro (intermediate) filters Powder supply 230 V, 50Hz, Single Phase Documentation DQ, IQ, OQ Test CertificateFAQs of Reverse Laminar Air Flow:

Q: What type of frame material is used for the Reverse Laminar Air Flow?

A: The frame material used for the Reverse Laminar Air Flow is Stainless Steel.Q: What type of filter is integrated into this product?

A: The Reverse Laminar Air Flow is equipped with HEPA Filter (Minipleated HEPA Filters) that can capture down to 0.3-micron particles with an efficiency of 99.999% (EU14) and is DOP-tested with SS-304 Protective Grill.Q: Is the Reverse Laminar Air Flow automatic or manual?

A: The Reverse Laminar Air Flow comes with an Automatic Grade system.Q: What industry applications are suitable for this product?

A: The Reverse Laminar Air Flow is suitable for Pharmaceutical Industries and Laboratories.Q: What is the warranty duration for the Reverse Laminar Air Flow?

A: The product comes with a 1-year warranty.Q: What is the power and voltage specification of the Reverse Laminar Air Flow?

A: The power specification is 230 V, 50Hz, Single Phase, and the voltage is 230 Volt.Q: What dimensions are available for the Reverse Laminar Air Flow?

A: The dimensions (L*W*H) are customizable as per requirement in millimeters (mm).

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Reverse Laminar Air Flow Unit Category

SOLVENT DISPENSING BOOTH

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Weight : As Per Specific Size Requirement Kilograms (kg)

Material : Stainless steel

Condition : New

Filters : HEPA FILTER, ACTIVATED CARBON FILTER, PRE FILTER

Sampling Booth

Price 100000 INR / Piece

Minimum Order Quantity : 1 piece Piece

Weight : 100150 Kilograms (kg)

Material : Stainless steel

Condition : New

Filters : pre Filter , Indermidiate Filter , Minipleated Hepa Filter , Exhaust Hepa Filter

Reverse Laminar Air Flow Unit (RLAF)

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece Piece

Weight : As Per Specific Requirement Kilograms (kg)

Material : Stainless steel

Condition : New

Filters : HEPA Filter, Mini Pleat HEPA Filter, Pre Filter, Fine Filter

Dispensing Booth

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit Unit

Weight : As Per Specific Size & Requirement Kilograms (kg)

Material : Stainless steel

Condition : New

Filters : HEPA Filter 0.3 Micron

GST : 24AAJCP9698P1Z7

|

PROTECH AIR SYSTEMS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry