Pharmaceutical Clean Room

Price 2000 INR/ Square Meter

Pharmaceutical Clean Room Specification

- Voltage

- 230 Volt (v)

- Weight

- As Per Specific Size Requirement Kilograms (kg)

- Feature

- As Per Specific Requirement

- Filters

- HEPA Filter, Mini Pleat HEPA Filter, Pre Filter, Fine Filter

- Filter Type

- HEPA Filter

- Type

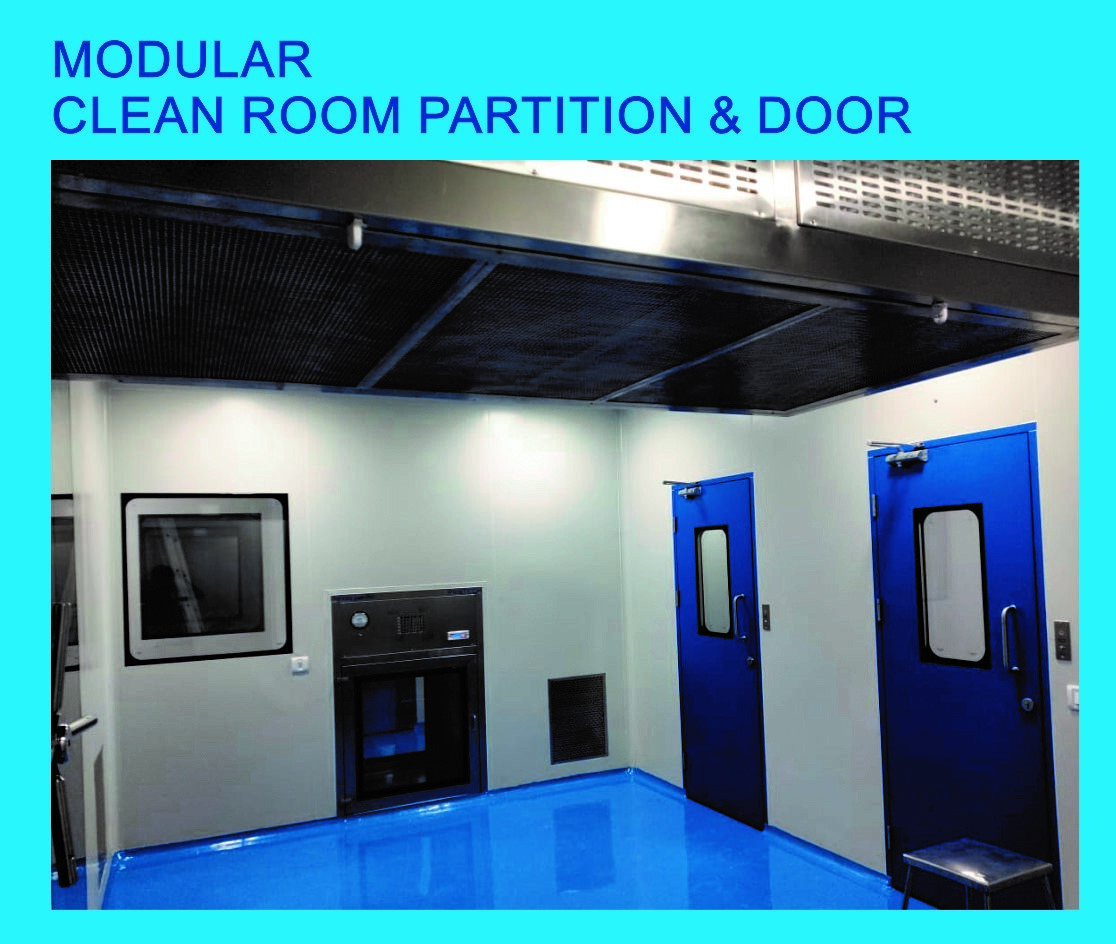

- Modular Clean Room

- Frame Material

- Powder Coated Steel Sheet

- Floor

- As Per Specific Requirement

- Power Consumption

- 230 V, 50Hz, Single Phase Volt (V)

- Material

- Galvanized steel

- Application

- TISSUE CULTURE , PHARMA COMPANY , LABORATIRIES , FOOD COMPANY , ENGINEERING COMPANY , MILK COMPANNY E.T.C

- Door

- As Per Specific Requirement

- Dimension (L*W*H)

- As Per Specific Requirement Millimeter (mm)

- Lighting

- As Per Specific Requirement

Pharmaceutical Clean Room Trade Information

- Minimum Order Quantity

- 500 Square Meters

- FOB Port

- Ahmedabad

- Supply Ability

- 10000 Square Meters Per Month

- Delivery Time

- 3 Week

- Sample Available

- Yes

- Sample Policy

- If order is confirmed we will reimburse the sample cost

- Packaging Details

- As per Standard Requirement

- Main Domestic Market

- All India

- Certifications

- As Per Specific Requirement

About Pharmaceutical Clean Room

Pharmaceutical Clean Room is typically used for the scientific research, and manufacturing purposes. Basically, the clean room is the controlled environment, where the pollutants level is nominal. Generally, the clean room contains instruments and tools, which have the ability to remove the dust, aerosol particles, airborne microbes, and chemical vapors. The offered clean room is designed and manufactured by a team of dexterous professionals, who have incorporated top-notch assembling tools and pieces of equipment, for which, the extended durability and exceptional performance of the Pharmaceutical Clean Room are guaranteed.A micron (or micrometer) is a millionth of a meter. A human hair is around 100 microns thick. Particles less than 50 microns cannot be seen by a naked eye. Bacteria measure 1 or 2 microns.HEPA filtersHEPA stands for High-efficiency particulate air. HEPA filters are one of the most important elements of a cleanroom. They consist of a large, box shaped filter that removes airborne particles of specific sizes very efficiently. They must also be monitored and tested regularly to make sure they are still integral.HEPA filters are composed of a mat of randomly arranged fibers, which are typically composed of fiberglass with diameters between 0.5 and 2.0 microns. Key factors affecting function are fiber diameter, filter thickness, and filter face velocity.Dispersed oil particle (DOP) testing / Integrity TestingDOP testing or integrity testing is a testing procedure to ensure that a HEPA filter meets its efficiency specification and is properly seated and sealed in its frame.AirlockAn airlock is a room where personnel, materials or equipment are transferred into or out of a cleaner environment. It can be the size of a small cupboard, or a large room where personnel change into and out of cleanroom garments, or where a forklift can enter.Clean room classification ISO ClassThis refers to the level of cleanroom particulate cleanliness based on a number of airborne particles of a certain size per cubic meter. ISO 8 is the starting cleanroom level. A sterile cleanroom for the pharmaceutical industry will need to achieve ISO 5. Classes better than ISO 5, that is ISO 4 are generally only required for the electronics industry.Clean room classification Annex 1 or ISO?Grades A through to D refer to cleanroom cleanliness for sterile products only, these Grades can be related to the ISO Classes, but they are not the same.The classification of 100, 10,000, and 100,000 normally refers to the withdrawn FED-STD-209 E Airborne Particulate Cleanliness Classes in Cleanrooms and Clean zones which was cancelled on November 29, 2001 by the U.S. General Services Administration (GSA).This was superseded by International Standard ISO 14644, Cleanrooms and controlled environments-Part 1: Classification of air cleanliness, and Part 2: Specifications for testing and monitoring to prove continued compliance with ISO 14644-1.Room recovery rateThe time it takes from a contamination event to the room regaining its designed cleanliness level as per the GMP requirements.Particle countA test that samples a fixed volume of air and captures, filters and counts airborne particles by their size. This is performed when the cleanroom is at rest or in operation. For pharmaceutical operations, both airborne viable (alive) and non-viable (not alive) particle counts are performed. This is performed as part of the certification of a cleanroom and during regular environmental monitoring.FAQs of Pharmaceutical Clean Room:

Q: What is the frame material used in the Pharmaceutical Clean Room?

A: The frame material used is powder-coated steel sheet.Q: What type of clean room is the Pharmaceutical Clean Room?

A: It is a modular clean room.Q: What filter types are provided in the Pharmaceutical Clean Room?

A: The filters include HEPA Filter, Mini Pleat HEPA Filter, Pre Filter, and Fine Filter.Q: What is the power consumption specification of the Pharmaceutical Clean Room?

A: The power consumption is 230 V, 50 Hz, Single Phase Volt (V).Q: What are the typical applications of the Pharmaceutical Clean Room?

A: The clean room is suitable for Tissue Culture, Pharma Companies, Laboratories, Food Companies, Engineering Companies, Milk Companies, etc.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Modular Cleanroom Partitions Category

Modular Cleanroom Partition Panel

Price 150000.0 INR / Set

Minimum Order Quantity : 1 Set

Material : Stainless steel

Filters : HEPA Filter, Mini Pleat HEPA Filter, Pre Filter, Fine Filter

Type : Modular Clean Room

Condition : New

Clean Rooms Doors For Pharmaceuticals

Price 7000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless steel

Type : Modular Clean Room

Condition : NEW

GST : 24AAJCP9698P1Z7

Office :- B 502, Fifth Floor, World Trade Tower (WTT), Behind Skoda Showroom, S.G. Highway, Makarba,Ahmedabad - 380051, Gujarat, India

Phone :08045479501

|

PROTECH AIR SYSTEMS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry