- Home Page

- Company Profile

-

Our Products

- Laminar Airflow Unit

- Class II Bio Safety Cabinet

- Laminar Air Flow Unit

- Air Filters

- Reverse Laminar Air Flow Unit

- Pass Box

- Fume Hood

- Modular OT Room

- Modular Cleanroom Partitions

- Air Curtain

- Laboratory Furniture

- HEPA Filter

- Air Shower

- Ventilation System

- Positive Pressure Modules

- Industrial Dehumidifier

- Turnkey Projects

- Modular Operation Theatre

- Air Handling Unit

- Fan Filter Unit

- Air Shower Unit

- Axial Flow Fan

- Biosafety Cabinet

- Ceiling Suspended Laminar Air Flow Unit

- Centrifugal Blower

- De Humidifier

- Dispensing Booth

- Dynamic Pass Box

- Fan Filter Unit (FFU)

- Garment Storage Cabinet

- Horizontal Laminar Air Flow Unit

- Mobile Laminar Air Flow Unit

- Modular Partition

- Positive Pressure Module

- Reverse Laminar Air flow Unit(RLAF)

- Sampling Booth

- Static Pass Box

- Sterile Garment Storage Cabinet

- Vertical Laminar Air Flow Unit

- Contact Us

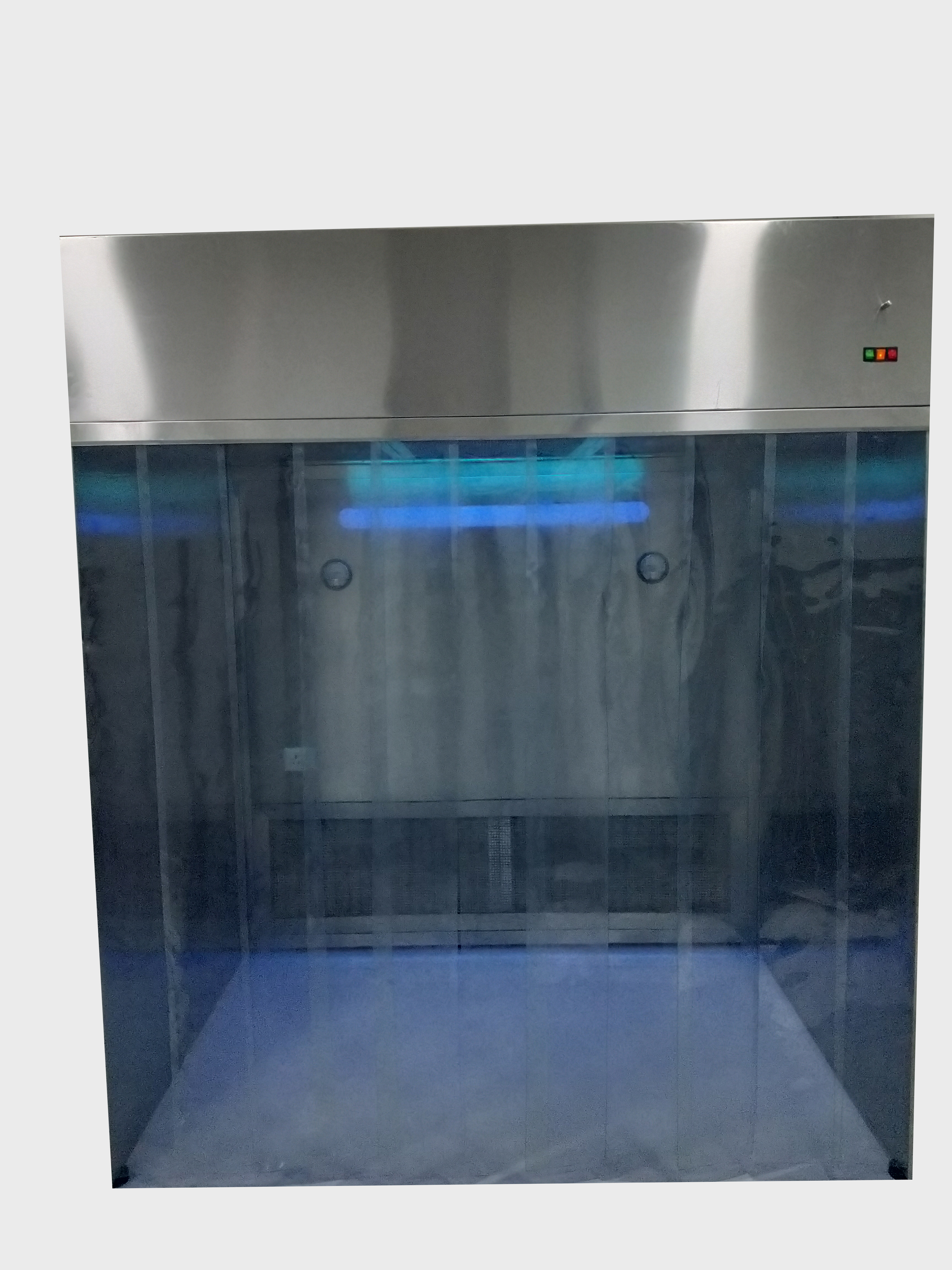

Dispensing Booth

100000 INR/Unit

Product Details:

- Air Flow Vertical kilometer/hr (KPH)

- Power Consumption 230 V Volt (V)

- Type Other

- Filters HEPA Filter 0.3 Micron

- Weight As Per Specific Size & Requirement Kilograms (kg)

- Voltage 230 V Volt (v)

- Material Stainless steel

- Click to view more

X

Dispensing Booth Price And Quantity

- 100000 INR/Unit

- 100000.00 - 1000000.00 INR/Unit

- 1 Unit Unit

Dispensing Booth Product Specifications

- 230 V Volt (V)

- Other

- Vertical kilometer/hr (KPH)

- As Per Specific Size & Requirement Kilograms (kg)

- HEPA Filter 0.3 Micron

- As Per Requirement Millimeter (mm)

- As Per Specific Requirement

- Laboratories, Pharmaceutical Industries, Clean Room

- 230 V Volt (v)

- Stainless steel

- As Per Specific Requirement

- HEPA Filter

- Stainless Steel

Dispensing Booth Trade Information

- Ahmedabad

- 15 Unit Per Month

- 3 Week

- Yes

- If order is confirmed we will reimburse the sample cost

- Middle East, Asia, Africa

- All India

- As per Requirement

Product Description

TheStainless Steel Dispensing Bootheliminates powder contamination to protect the operator and the surrounding environment. It is designed to handle powder under aseptic conditions for optional G.M.P. Specification Cleanliness Class 100 / ISO CLASS 5 / M 3.5 AREA Velocity at Grill 90 10 FPM Material of Construction S.S 304 HEPA Filter Mini pleated HEPA Filters down to 0.3mic. particulate at an efficiency of 99.999% (EU14) duly tested on DOP tested with SS-304 Protective Grill Intermediate Filter Micro V Filter down to 5mic. Particulate at an efficiency of 99% (EU9) enclosed in aluminum frame with epoxy sealing (Washable Type) Pre-Filters Pre-Filter down to 10mic. Particulate at an efficiency of 95% (EU4) enclosed in aluminum frame with epoxy sealing (Washable Type) Blower Assembly Dynamically and statically balanced motor and blower Side Panels Both sideSS-304 Double Skinned PUF Insulated Panel Front Door Do with Flexible PVC Strip Curtain Electrical 1) On/Off Switch2) Fluorescent Light3) U V Light4) Auxiliary Socket Pressure Gauge Magnahelic Gaugeone is to check the pressure drop across the HEPA filter and other for pre & micro V (intermediate) filters Powder supply 230 V, 50Hz, Single Phase Documentation DQ, IQ, OQ Test CertificateFAQs of Dispensing Booth:

Q: What material is used for the frame and overall construction of the Dispensing Booth?

A: The frame and overall construction of the Dispensing Booth are made of stainless steel, ensuring durability and high-quality performance.Q: What type of filter does the Dispensing Booth use, and what is its filtration capacity?

A: The Dispensing Booth is equipped with HEPA filters that are capable of filtering particles up to 0.3 microns.Q: Can the dimensions of the Dispensing Booth be customized?

A: Yes, the dimensions of the Dispensing Booth can be customized as per specific requirements.Q: What industries is the Dispensing Booth suitable for?

A: The Dispensing Booth is suitable for laboratories, pharmaceutical industries, and clean-room applications.Q: What is the voltage requirement for the Dispensing Booth?

A: The Dispensing Booth operates on a voltage of 230 V.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese